Rocky Mountain Electric

Industrial Service Specialists

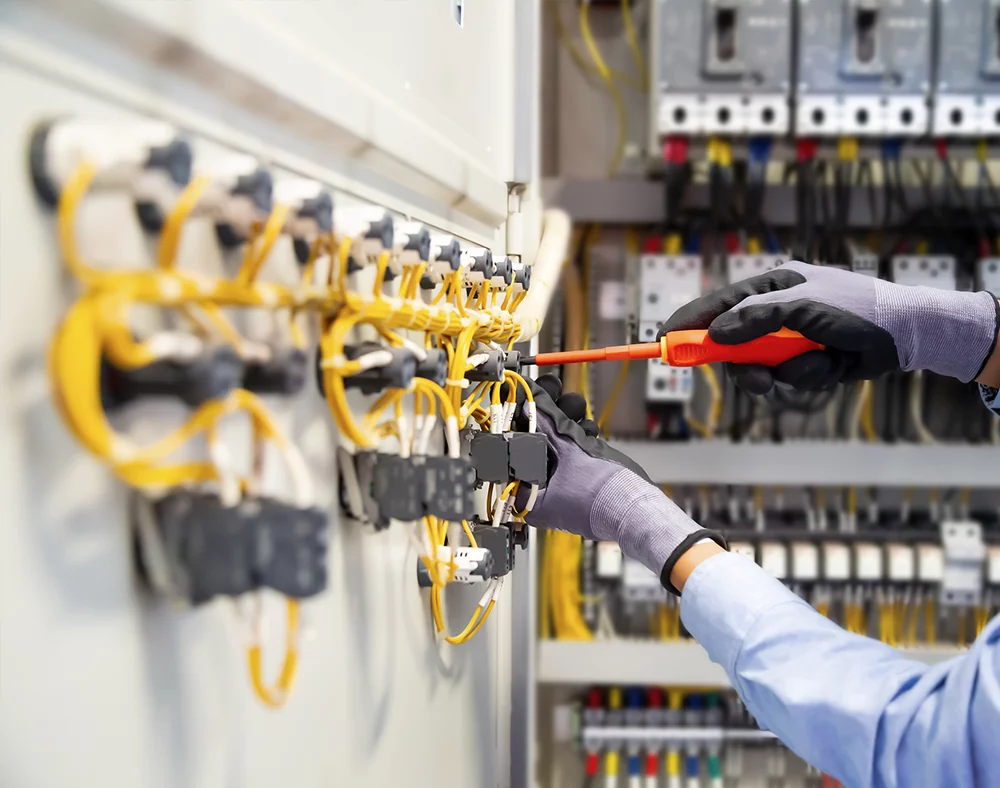

Rocky Mountain Electric knows that your industrial facility’s electrical system is the life-blood of your business. Rocky Mountain Electric’s team of Industrial Service Specialists is at the ready with 24-hour emergency service. Our on-call electrical systems maintenance and emergency repair will ensure your industrial operation stays up and running, because it has to!

From clean room facilities, to manufacturing operations, food processing plants, and more, our knowledgeable, well-trained, and personable electricians have state-of-the-art tools and equipment, along with expert solutions to any electrical problems.

* Rocky Mountain Electric is a BBB accredited business with an A+ rating

Industrial

Electrical Services Include:

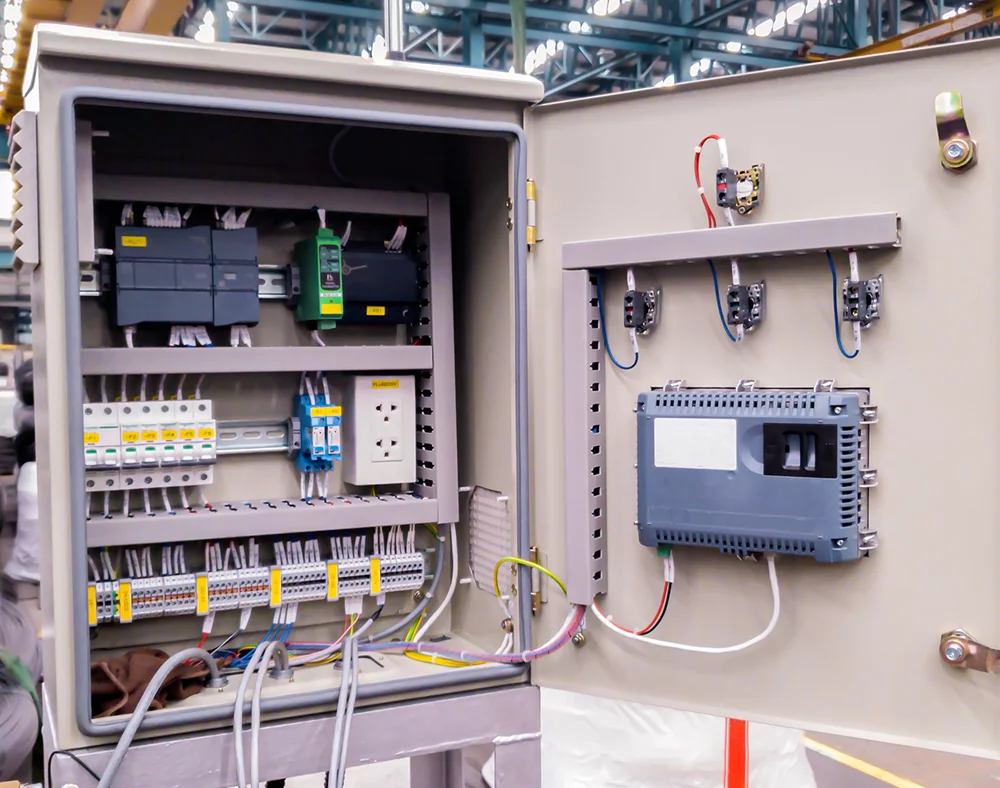

- Controls Instrumentation

- Data Center & Network Services

- Equipment Service, Maintenance, & Repair

- Facility Power

- High Bay & Low Bay Lighting

- Motor Control Service, Troubleshooting, & Repair

- Power Distribution

Our Industrial Clients Include:

- Biotechnology Laboratories

- Bottling Plants

- Clean Room Facilities

- Dairy, Feed, & Seed Facilities

- Food Processing Facilities

- High-Tech Manufacturing Facilities

- Petrochemical Facilities